Typically, molds are made to replicate metal and plastic components. It is the most economical method of launching your items at scale after the prototypes and the market have been tested. Sharp corners, uneven wall thicknesses, and other elements that impede material flow should be avoided in molding designs.

3ERP is considered amongst the best Mold maker because of their best services. Injection mold-making is a critical system in the production of plastic parts, and it entails numerous precise and interrelated steps. Mold-making is a complex procedure that requires a high stage of ability and experience. At the same time as every situation is precise, a regular order for a set of molds ought to look something like this.

Key Steps in the Making Process

Here’s an outline of some key steps within the mold-making process:

Concept & Design

Step one in mold making is the conceptualization and layout of the mold. Engineers and architects create particular plans primarily based on the element’s specifications, which encompass dimensions, cloth type, and practical necessities. They use CAD (Computer-Aided Design) software programs to broaden a 3D model of the part and mold. This degree considers elements such as component geometry, draft angles, wall thickness, and gating locations. A powerful layout ensures the mold will produce first-rate parts while minimizing cycle times and cloth waste.

Material Selection and Procurement

The following step involves deciding on and procuring materials for the mold. Commonplace substances encompass device steels like P20 or H13 for their sturdiness and machinability, or aluminum for prototyping and brief production runs. The procurement technique includes sourcing exceptional substances that meet the desired requirements and tolerances. Right material choice is critical to the mold’s performance, affecting factors like put on resistance, thermal conductivity, and machinability.

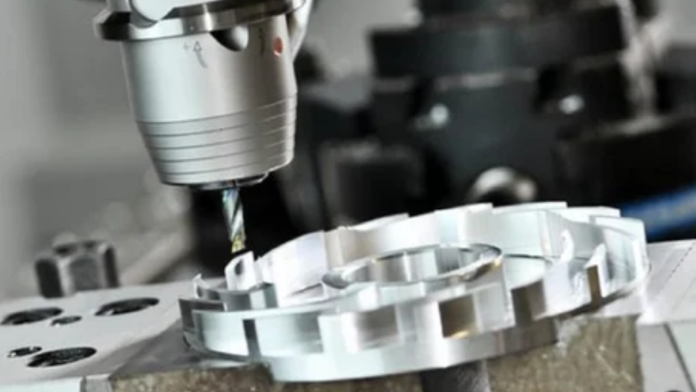

Machining and Fabrication

Machining and fabrication of the mold components is a critical degree where the design is translated right into a physical mold. High-precision CNC (Computer Numerical Control) machines, EDM (Electric Discharge Machining), and other advanced strategies are used to shape the mold components according to the design specifications. Machining consists of creating the mold cavity, middle, cooling channels, and other essential functions. Surface finishing, which includes polishing or texturing, is also achieved to gain the specified surface of the molded parts.

Assembly and Fitting

Once the mold components are machined, the assembly and fitting method begins. This entails assembling the individual components right into a complete mold. During this stage, the mold is cautiously aligned and outfitted collectively to make sure that all parts interact effectively. Any discrepancies or misalignments are corrected to ensure proper function. The mold is examined for fit and function, making sure that the components flow as designed and that the mold can open, near, and eject components without issues.

Testing and Validation

Testing and validation contain conducting mold trials to make sure the mold produces parts that meet design specifications. The mold is hooked up to an injection molding gadget, and a tribulation run is achieved to evaluate component quality, cycle time, and any capacity issues. Changes can be made to optimize the mold’s performance, which includes refining cooling channels or adjusting ejection mechanisms.

Maintenance and Fine-Tuning

Preservation and pleasant-tuning are ongoing strategies that make certain the mold remains in the highest quality condition during its lifecycle. Regular maintenance consists of cleansing, lubricating shifting elements, and examining for harm. Satisfactory-tuning adjustments may be made based totally on manufacturing comments to improve element first-rate or cycle time. Proactive maintenance extends the mold’s life and minimizes downtime, ensuring regular production fine. Before sending the mold to the customer, manufacture them in line with the final specifications.

Sum Up

Every step is crucial in ensuring the mold’s exceptional and overall performance, in the long run, main to efficient and effective manufacturing of great plastic elements. Via carefully coping with every degree, manufacturers can produce molds that meet specific specifications and withstand the trials of excessive-extent production.